How can Gravitilab help the Materials Science industries?

Materials Science industries focus on researching and developing new materials and this activity on earth is always affected by the force of gravity – this ‘interference’ affects the performance of materials in isolation and in combination as processes such as bonding and sedimentation at a molecular level are impacted. Gravitilab gives materials scientists access to gravity free environments (“microgravity”) as well as offering access to the unique Space environment outside the earth’s atmosphere where temperatures, pressure and radiation are very different.

There are a myriad of industries that can benefit from access to microgravity and Space environments including but not limited to semiconductors, alloys, building materials, fibre optics, 3D printing, pharmaceuticals, composites, electronics, sensors, nanomaterials, chemicals, energy – the list goes on.

So how does this happen?

Gravity influences buoyancy-driven convection, sedimentation, and hydrostatic pressure and can create defects and impurities in the internal structure of materials, which in turn alter their properties. The virtual absence of these gravity-dependent phenomena in microgravity allows researchers to study underlying events that are normally obscured by the effects of gravity, and which are therefore difficult or impossible to study quantitatively on Earth. So, by accessing microgravity, materials scientists can develop new and better materials.

One example of how microgravity can help the development of manufacturing processes is ZBLAN, a type of fluoride-based optical fibre glass that has the potential to perform up to 100 times more efficiently than traditional silica-based fibres. On Earth, gravity-driven forces cause impurities to form in the fibres through the formation of crystallites. By conducting suborbital experiments in microgravity, it is possible to produce ZBLAN optical fibres without these crystals, providing the potential for superior data-transmission, improving the efficiency and cost of communications systems and deployments such as in sensors for the aerospace and defence industries and in medical devices such as laser scalpels.

Microgravity testing also enables significant innovations in sectors such as additive manufacturing, bearing the potential to revolutionise our uses of 3D printing. The manufacture of the first 3D-printed object in Space was first demonstrated in 2014 as part of a collaborative effort between NASA and Made In Space. Not only can different materials be 3D printed in Space but in time this attribute could reduce the need to resupply missions to spacecraft, expanding the possible durations and distances of Space travel.

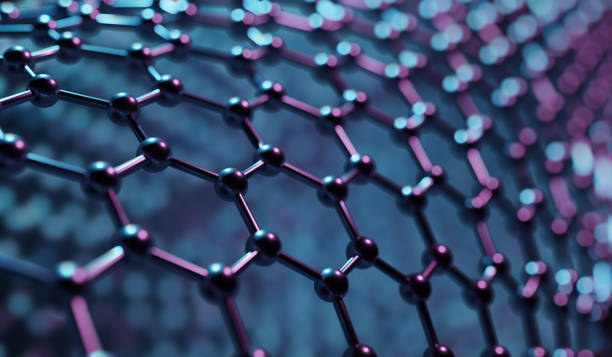

Moreover, microgravity allows for the creation of totally new substances with myriads of potential uses. By growing carbon nanotubes on a surface in microgravity conditions, researchers at NASA’s Goddard Space Flight Centre were able to create a new material called “superblack” that absorbs 99% of all light, applicable in technology such as telescopes and other imaging systems that require a high level of light absorption. The creation of such an advanced material was only possible through access to Space conditions.

Microgravity also provides unprecedented insight into the relationship of particle shape and interparticle interactions in terms of dynamics and assembly structure in liquids. In 2018, researchers at the European Space Agency utilised microgravity to examine the behaviour of colloids, minuscule particles suspended in a liquid. The study showed significant differences in the behaviour of colloids in microgravity, opening new avenues for manufacturing cosmetics and liquids and use in technology such as optical devices.

How Gravitilab helps

Testing materials is a complex task as materials can generally only be subjected to one environment at a time. Gravitilab understands this, offering a range of materials testing services that underpin the importance of developing new and innovative materials through ‘synergistic’ testing and improving the risk against early failure through testing. Gravitilab’s range of materials testing services offer the chance to test materials in unforgiving environments, but at a cost and timeline that fits our customers’ qualification budgets and timeframes.

Our advanced technology includes a patented drop pod that releases from an uncrewed aerial vehicle (UAV) at a specific height. During the pod’s controlled descent, a microgravity environment is generated, providing an affordable and accessible way to conduct microgravity research and testing. For longer durations of microgravity Gravitilab is developing suborbital rockets which will also provide access to Space environments.

If you’d like to know more about how Gravitilab’s can help your Materials Science research, please get in touch with Brian Zielinski-Smith at brian.zs@gravitilab.space.